The following are common mistakes we see during retrofit construction. Also, a reminder that no construction should be started until the homeowner has received CRMP's approval to begin.

Common Construction Mistakes

|

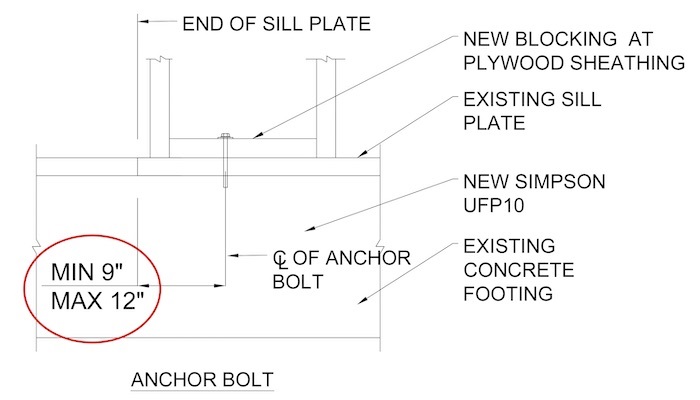

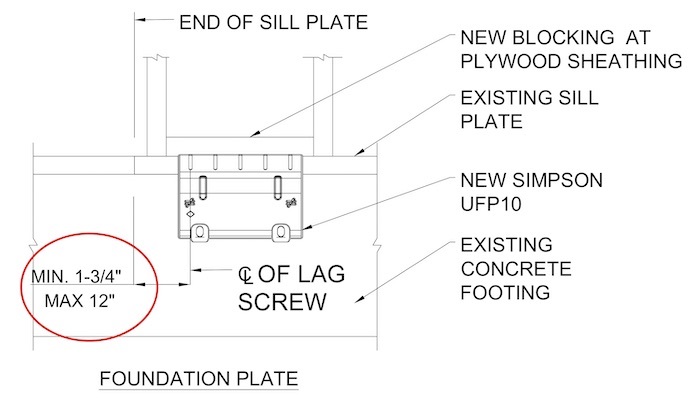

#1 Incorrect Bolt/screw end distance in mudsill

|

|

|

|

|

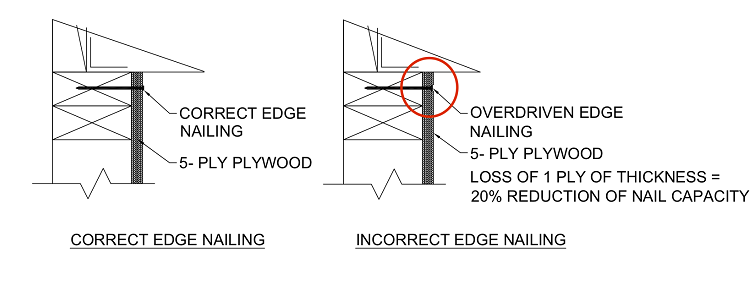

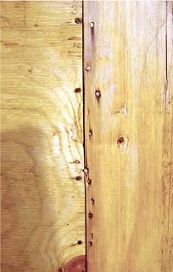

#2 Nails overdriven or misplaced

|

|

|

Nails on Seam |

|

#3 Bolts and nuts improperly installed

|

|

|

|

- Bolts should be straight and all nuts should be tightened as per manufacturer specifications.

- Bolts should be flush with the top of the nut.

|

|

#4 Use of non-approved angles, hold-downs, clips and foundation plates

|

|

|

- No work is required at the interior of the crawlspace. Hold-downs are always located at the ends of shear walls.

- Vertical angles have no lateral capacity and are not required by Chapter A3 or the plan sets. Note: the requirements for foundation plates include a minimum plate thickness, 2-1/2” diameter anchors and 3-1/4” diameter lag screws.

|

|

|

|

#5 Cripple walls >4’-0” must be designed by an engineer or using FEMA P-1100

|

|

|

- Walls greater than 4’-0” require special attention as they may require hold-downs at each end.

- Chapter A3, Plan Set A and the LA Standard Plan Set all require an engineered design for walls greater than 4’.

- Check with the building department to see if they allow use of FEMA P-1100.

|

|

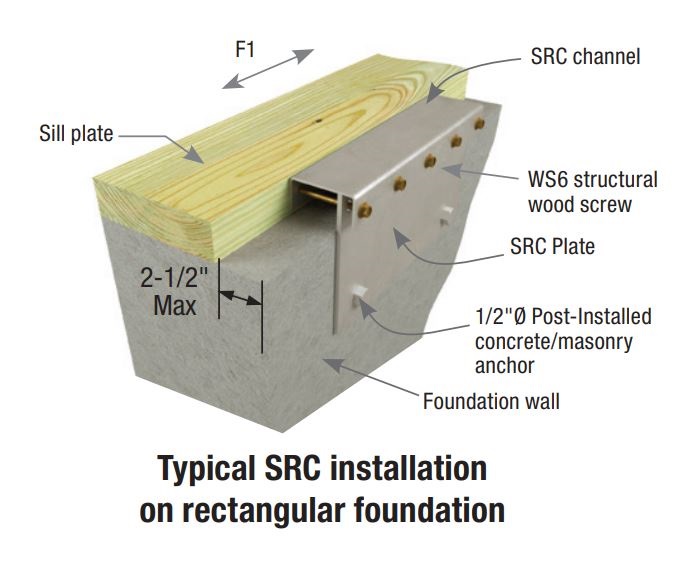

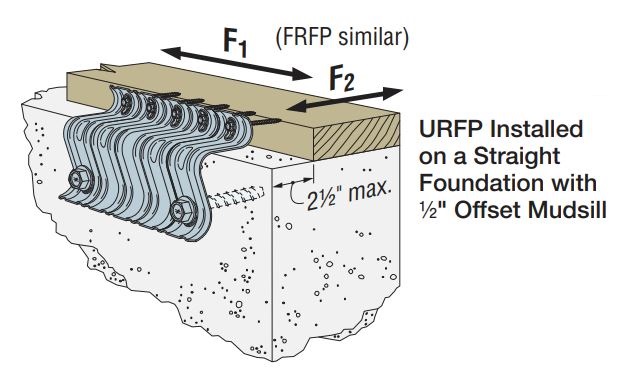

#6 Only Use Manufacturer Specified Concrete Anchors in Prescriptive Hardware

|

Mitek SRC Requires PowerStud® anchors |

- Prescriptive hardware such as the SRC or URFP must be installed per the manufacturer’s requirements unless a registered design professional specifies the anchor.

- Check the manufacturer’s requirements for approved concrete/masonry anchors.

(Note: LA Standard Plan Set #1 requires all anchors have current LARR approval.) |

Simpson Strong-tie URFP requires SET-3G, AT-XP, or Titen HD |